Video

1. Siemens touch PLC operating system

2.tanks material . inner layer SS 316. Middle and out layer SS304

3.Motor brand: AAB OR Siemens

4.Heating method : steam heating or electrical heating or no heating

5.power supply : three phase 220voltage 380voltage 460voltage 50HZ 60HZ for option

6.leader time 30 days

7. Compliance with GMP rules

8.Cooling water can be inserted into the interlayer to cool tank make material cool status

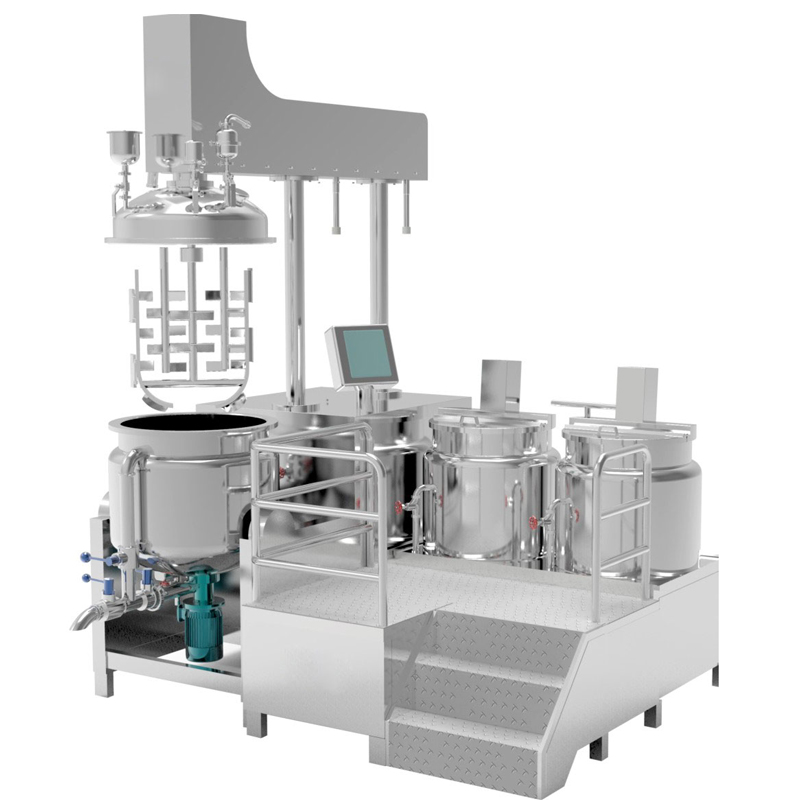

9. Homogenizer agitation and blade agitator can be used separately or simultaneously for large range process for difference process

10.Raw Material particle, emulsification, mixing, leveling, dispersion can be completed quicky reduce the batch time for more product making .

11.Frequency conversion speed regulating device can make the speed regulating according to the process.

12.The outer circulation vacuum homogenizing emulsifier is a high quality product newly developed machine

13.Under vacuum status . the material can not touch air . make sure the product has good fine

14.the homogeneous emulsification mode under the external circulation can make the dispersed phase be emulsified for a short time, and good mixing effectively

15. circulating and homogeneous discharging, also can be the main pot plus positive pressure discharging, convenient and fast .three discharging ways for more simple operation

16. simple operation and use, emulsifying and homogenizing effect is better

17.Solids and liquids can be added directly to the emulsification head and quickly

18.The emulsification and dispersion phases are added directly to the working head.

19.Material circulation, CIP cleaning, no additional pumps are required for discharge.

20.Better processing results, shorter processing time.

21. vacuum emulsifying pot is designed with vacuum system to pump the products of water and oil phase to main working pot , and remove bubbles during processing

22. Electric heating system can heat or cool the jacket in different production process. Steam heating is option .

23. Double direction blending and high shear homogenizer to ensure the emulsiyfing and mixing more evenly and effectively and quicly . It's the ideal cosmetics manufacturing equipment .

24. Might mixing and disperse viscously, solid and recipe

25..Various kind of raw material will be dissolve which is such as AES, AESA LSA.

26. During processing, save energy consumption and shorten batch time

27.simple in design and making make sure easier to operate, and the whole machine is more space-saving in terms of workshop height

28. PLC touch screen controller make easy to operate machine and full automatic process.

29. The homogenizer also works as a transfer pump for discharging finished product save human power

30.Variable speed for homogenizer1-3000R/min and agitator 1-63R/min;

Technical parameter:

| Model | Capacity(L) | Emulsify motor | Mixing motor | Toal power(steam/electric heating ) | Limited vacuum (Mpa) | Size (mm)L*W*H | ||||

| Main pot | Oil pot | Water pot | KW | RPM | KW | RPM | ||||

| 100 | 100 | 50 | 80 | 4 | 0-3000 | 1.5 | 0-63 | 10/37 | -0.095 | 2385*2600*200-2900 |

| 200 | 200 | 100 | 160 | 5.5 | 2.2 | 12/40 | 2650*3000*2400-3100 | |||

| 500 | 500 | 250 | 400 | 11 | 4 | 18/63 | 2850*3000*3000 | |||

| 1000 | 1000 | 500 | 800 | 15 | 5.5 | 30/90 | 3000*3100*3000 | |||

| 2000 | 2000 | 1000 | 1600 | 18 | 7.5 | 40/120 | 3100*3100*3000 | |||

Option

1.power supply: three phase : 220v 380v .415v. 50HZ 60HZ;

2.Capacity : 100L up to 5000L;

3.Motor brand : ABB. Siemens option;

4.Heating method: Electric heating and steam heating option;

5.control system plc touch screen. Key bottom;

6.Fixed type or Hydraulic lifting type or Pneumatic lifting;

7.variety of paddle designs meet difference requirement;

8.SIP is available upon request for cleaning process.